Prosthetic limbs have come a long way from the heavy, solid hands and legs of yesteryear, but it’s still difficult to pack a range of motion into them without complex or bulky machinery. But new research out of Cornell uses a cleverly designed 3D-printed mechanism to achieve speed and strength with simple construction — and it costs a lot less, too.

“Developing prosthetic limbs requires designers to make difficult trade-offs among size, weight, force, speed, and cost of the actuation system,” the researchers say in their paper. For example, they point out, state of the art mechanical prosthetic hands can cost well over ten thousand dollars, with the high-end motors inside alone costing hundreds each. Cheaper hands use cheaper components, of course, which might mean that the hand can grip hard but not quickly, or vice versa.

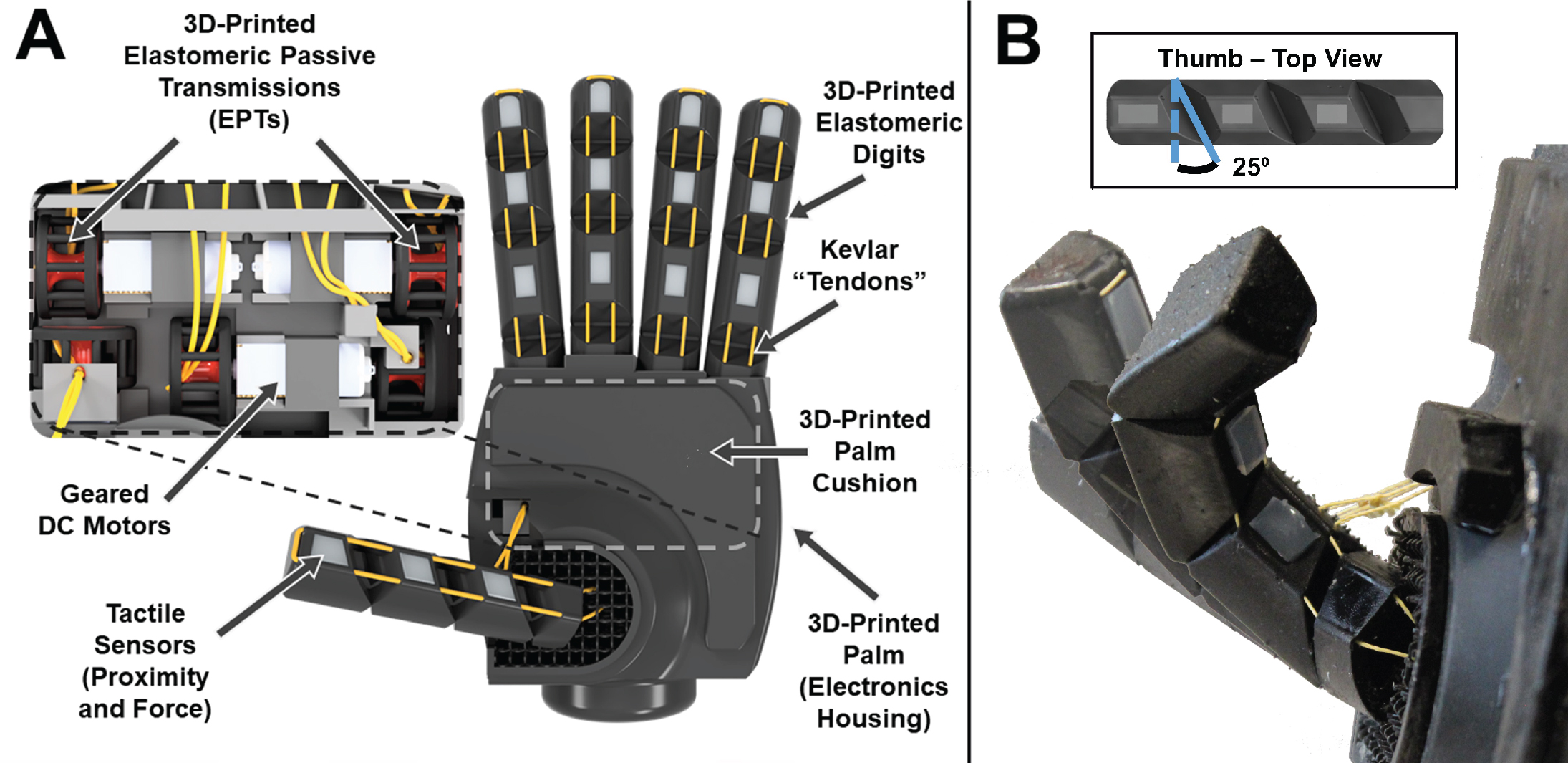

This is partly because a mechanical hand needs to be able to adjust the force it’s applying very quickly on the fly, and this usually involves some kind of variable transmission or dynamic gear ratio. But Kevin O’Brien and his colleagues developed a new way to have the motor adjust its speed and force without using hundreds of finely-machined components. In fact, it and the hand it actuates can be almost entirely 3D printed.

It works like this: the fingers of the hand are controlled, like many other such hands and indeed our own, by flexible cords that run along their lengths. These cords can be tightened or slackened to make the fingers take different positions, and that’s often done by having a spool take up the slack or deal it out. It’s this spool that must move precisely and is the end point of the complex gearing mentioned above in other hands.

But in the ADEPT hand (adaptively driven via elastomeric passive transmissions — we’ll stick with the acronym) these spools have in their centers a flexible cylindrical core, the shape of which can be modified by tightening a separate “tendon” around it. When the tendon is loose, the core is wider and spins quickly, producing fast, responsive movement. When the tendon is tightened, the core is reduced in radius and correspondingly increases in torque while decreasing in speed.

There’s no switching of gears, no meshing of teeth — if the hand determines that it needs just a little bit more torque to hold something, it can get it by tightening the tendon just that little bit. And as soon as it needs to quickly release or catch something, the tendon can loosen up and the fingers move quickly and lightly.

This simplicity and the ease of manufacturing make this much cheaper than other options, while it still provides a great deal of versatility and responsiveness.

“The benefits of elastomeric transmission systems are that they can be 3D printed quickly (50 per hour), cheaply (<$1 per part), and in many compact form factors,” the researchers wrote. A whole hand could be built for under $500, they estimate.

Unfortunately the materials aren’t quite up to the task just yet — the part that’s constantly having its shape adjusted tends to degrade, though they managed to get it to the point where it could be adjusted about 25,000 times before failing (not catastrophically, just not doing its job well enough any more). That may sound like a lot, but your fingers move a lot. So there’s still work to do before this is a realistic replacement for other mechanical parts.

Still, it’s a promising approach and general enough that it could also be used in artificial legs, arms, and exo-suits. You can read more at Science Robotics.

Read Full Article

No comments:

Post a Comment